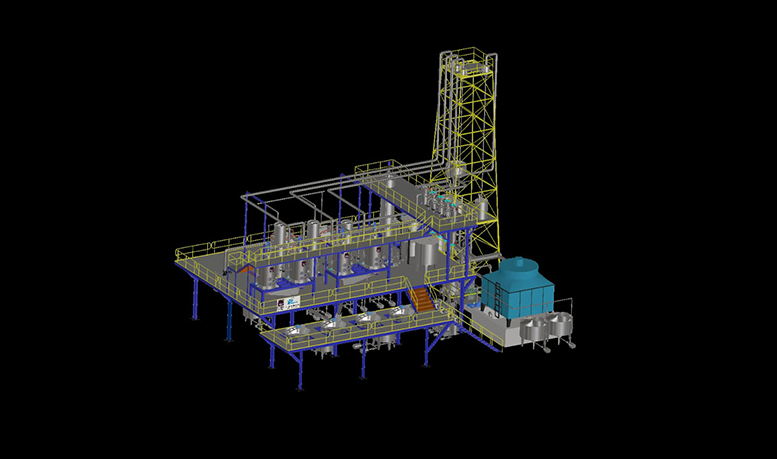

We’re excited to share a glimpse into our upcoming innovations in sustainable and efficient process engineering. These projects are currently in the advanced stages of design, with mechanical and process workflows nearing finalization.

A fully automated production facility designed to convert organic waste and starch-based feedstock into high-yield citric acid. With an estimated conversion efficiency of 70–80% (based on starch content), this plant exemplifies our focus on resource optimization and green chemistry.

Utilizing cassava as a feedstock, this facility will enable efficient and sustainable lactic acid production. This process not only supports agricultural value chains but also delivers a cost-effective solution in bioplastic and food-grade lactic acid markets.

A custom-engineered unit with dual-stream processing

Primary Juice → Jaggery Powder

Secondary Juice → Brown Sugar

We’re integrating Mechanical Vapour Recompression (MVR) to drastically reduce boiler energy consumption—making this a standout example of energy-efficient design.

We are excited to announce an upcoming project for the design, technology provision, and plant commissioning of a 200 TCD (tons per day) sugarcane-based jaggery production facility. This project utilizes skid-mounted engineering to ensure efficiency, modular design, and ease of installation.

Our client currently produces 2 tons/day using traditional open pan methods. We’re engineering a fully skid-mounted, automated system capable of

A fully automated facility designed to convert diverse organic feedstocks—ranging from cellulose to starch derivatives—into high-quality dry yeast. Incorporating one-time engineering, custom skid-mounted modules, and advanced automation, this plant ensures optimal yields, consistent product quality, and efficient scalability.